Get help from our warehouse optimization experts

Backed by our extensive experience and collective knowledge, we at Weland Solutions regard ourselves as experts in warehouse optimization and automated solutions. Based on your needs and requirements, we can make proposals for how your warehouse can be optimized in order to achieve maximum efficiency.

This isn’t just about exploiting the available warehouse space and getting the largest storage volume in the smallest possible area, it’s also about enabling an increase in picking speeds and the creation of a better working environment. Of course, we make sure that your existing business system is integrated in our logistics solution, and, in order to ensure that you have as good a turnkey solution as possible, we also make proposals for picking solutions to use and efficient peripheral equipment.

The Process

Kick-off – we listen

At our first meeting, we will work with you to review your business, listen to what you have to say, and collect facts. This gives us all the information we need in order to analyze where improvements can be made using our products, software, and picking solutions.

Proposal with Compact solution

The next time we see each other, we give a presentation of what your warehouse solution could look like, what the changes mean, and the size of the estimated investment. At the same time, we also give an estimate of how quickly the investment will pay for itself. You get a proposal for a turnkey solution with vertical storage lift(s), system solution, accessories, installation, training, and maintenance options.

Fine tuning

Once you’ve decided that you want to partner with us, we can work together to fine tune our proposed Compact solution. We go through our quote with a fine tooth comb and address all questions.

Ordering

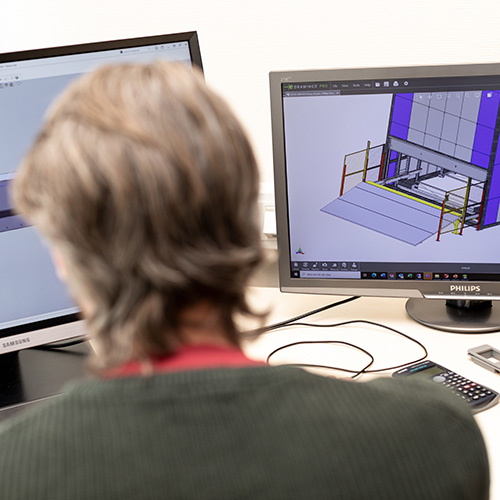

As soon as you submit your order, the manufacturing process and joint project planning work begin. Your vertical storage lift is manufactured in our factory in Gislaved, which is also home to our team of designers.

Training

We train you in the functionality of the vertical storage lift on site during installation. Handling training is available either on site at your premises or at Weland Solutions.

Preparation

As soon as you submit your order, the manufacturing process and joint project planning work begin. Your vertical storage lift is manufactured in our factory in Gislaved, which is also home to our team of designers.

Installation and commissioning

As a rule, each vertical storage lift takes no more than four days to install. Our installers are used to working in different surroundings with all imaginable challenges.They remain on site all the way to commissioning and will not complete the handover until we have made sure that you have received training in the basic functions and safety regulations applicable to your new vertical storage lift.

Maintenance – contract

Regular maintenance will ensure that your vertical storage lift will work for a long time without unnecessary stoppages. By signing a maintenance contract, you can guarantee that both regular maintenance and any emergency measures are managed in the best possible way.

Maintenance – development

You are always welcome to contact us when you need help expanding, developing the storage system, or if your vertical storage lift needs relocating. Remember to plan in our courses for your operators, superusers, and mechanics.

Warehouse optimization

Adapting to your premises